In the field of surveying and mapping, what is the core reason why lidar has been sought after for a long time?

Is it the extraordinary sensing performance that LiDAR naturally possesses? Is it a three-dimensional point cloud containing a huge amount of information? Or "additional capabilities" such as timeliness and stability?

Today, Xiaohui takes everyone to find the answer from a small cut like "Mine Surveying and Mapping". Take the "Genius" LiDAR system of Surestar as an example, let's see how LiDAR wins the favor of the entire surveying and mapping circle?

Surveying and mapping needs in the mine

Mine surveying, as an important branch of surveying and mapping, is inseparable from surveying and mapping operations whether it is planning and design of mining areas, mine exploration and construction, production and operation management after completion, and even later mine management.

In addition, surveying, mapping and surveying also play an indispensable role in the safety of mining areas. As we all know, mining is a highly dangerous industry. Factors such as landslides, collapses, blasting, mechanical injuries, falling from heights, vehicle injuries, and electrical injuries in the mining area all threaten the lives of mine workers at all times.

To ensure the safety of mining production, it is necessary to have a comprehensive and accurate grasp of the overall terrain and geomorphology of the mining area in order to do a good job in formulating safety rules and regulations, arranging full-time safety personnel, setting up an accident emergency mechanism, and regularly conducting safety drills. And this is where the surveying and mapping equipment comes in.

Nowadays, under the dual promotion of industrial intelligence and the performance development of surveying and mapping products, UAV-borne lidar systems are increasingly appearing in safe operation scenarios in mining areas.

Relying on its outstanding advantages in perception performance, lidar can well complete the surveying and mapping operations of the entire mine including the mining surface, mining slopes, dumping grounds, and tailings ponds. In scenarios such as safety inspections and emergency rescue response, UAV-borne lidar systems have also received increasing attention from mining companies due to their lightness and high efficiency.

The perfect performance of "Genius"

This summer, in a mine safety accident emergency drill carried out by a mining branch of Inner Mongolia Baotou Steel Group, the domestic lidar leader Surestar independently developed and produced the Genius micro-UAV LiDAR system, which fully demonstrated a high The precision surveying and mapping LiDAR has a strong strength in obtaining three-dimensional spatial information of the terrain surface.

The scenario set in the exercise is: after heavy rainfall in the mining area, secondary geological hazards appear in the tailings pond and slope area, The mining area quickly started the first-level emergency plan, send multiple groups of drones to survey and map the area, strive to obtain the point cloud data of the slope measurement area of the tailings pond and construct a digital elevation model to grasp the site conditions.

Aerial view of test area

Test area

After the drill began, surveying and mapping personnel carried the Genius Lidar system and DJI M200 industry-grade UAV flying platform and other equipment according to the task, and quickly selected a location close to the scheduled operation area to set up a static ground reference station to ensure that the Genius Lidar system was flying. The data collected in the process is complete and accurate, and the drone assembly and Genius system mounting operations are performed simultaneously.

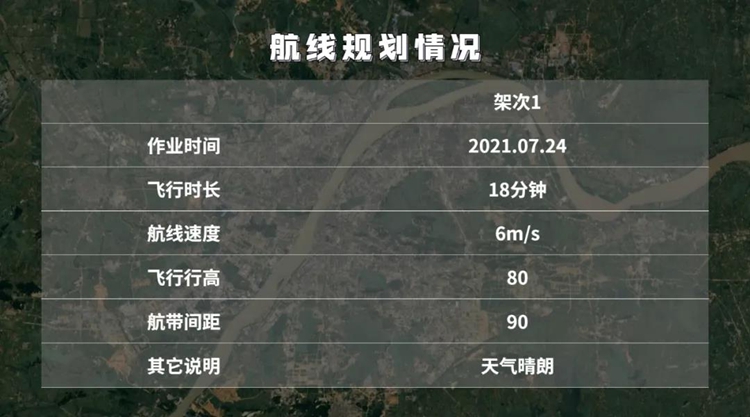

Next, the surveying and mapping personnel used the DJI Pilot software to plan the route according to the actual situation of the survey area and the operation requirements of "the observation time is within 20 minutes, and the main observation range is near the slope of the tailing pond". At the same time, in order to ensure the stability of data collection during the flight, the Genius lidar system completed in the route design is pre-energized and enters a power-on static state.

When the base station is turned on and the Power-on static time of the Genius system exceeds 5 minutes, the Genius lidar system is activated and starts to fly automatically according to the set route.

After the 18-minute flight operation was completed, 5 minutes after the ground-stationary Genius lidar system was powered off, the ground static reference station ended data collection, and the operation entered the data processing stage.

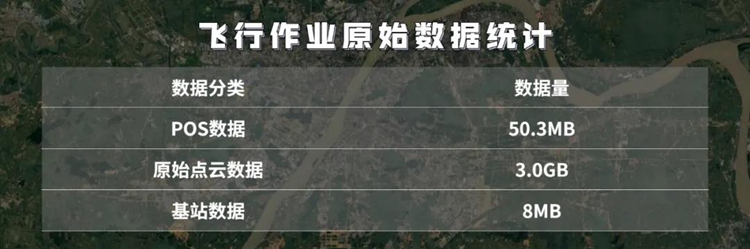

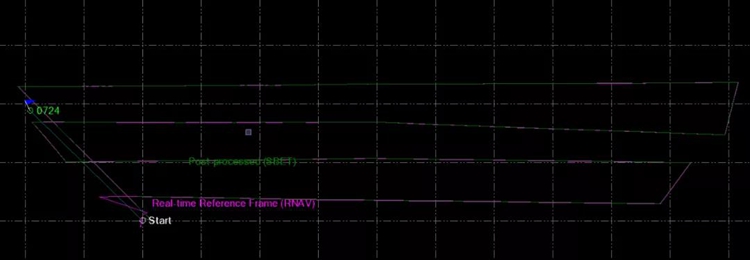

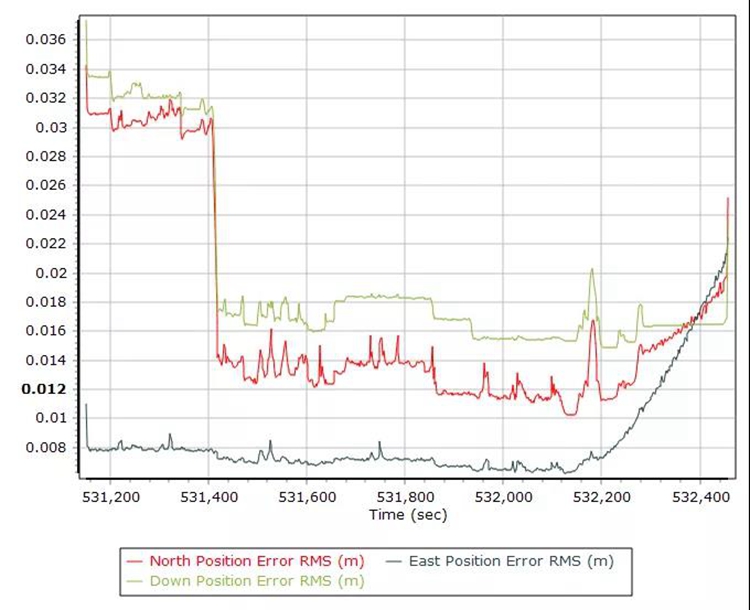

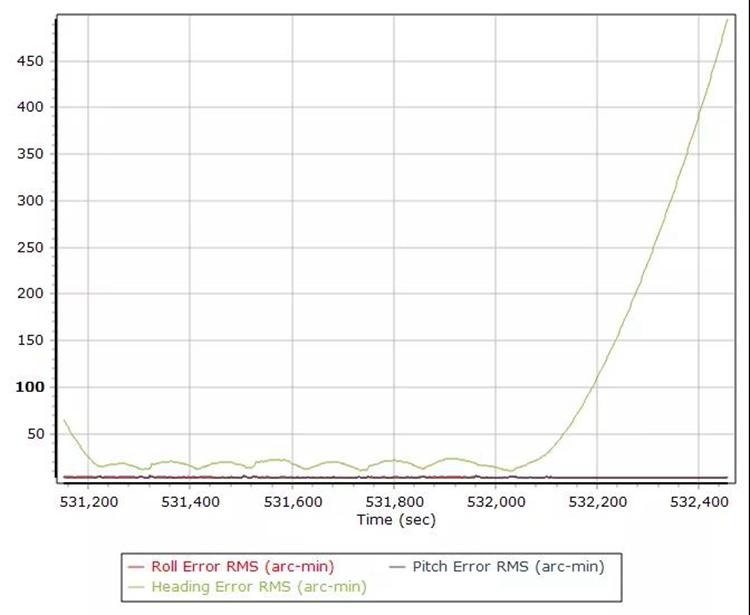

Through the trajectory calculation, the position and attitude accuracy of the Genius lidar system in this operation are known, so as to verify the accuracy of data collection.

Trajectory calculation

Position accuracy: The position accuracy in the east and north directions is less than 0.02m, and the position accuracy in the downward direction is less than 0.03m

Attitude accuracy: roll, pitch angle accuracy is about 5′, heading angle accuracy is about 20′

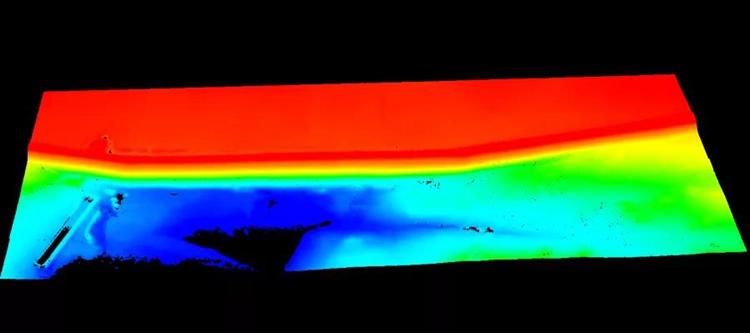

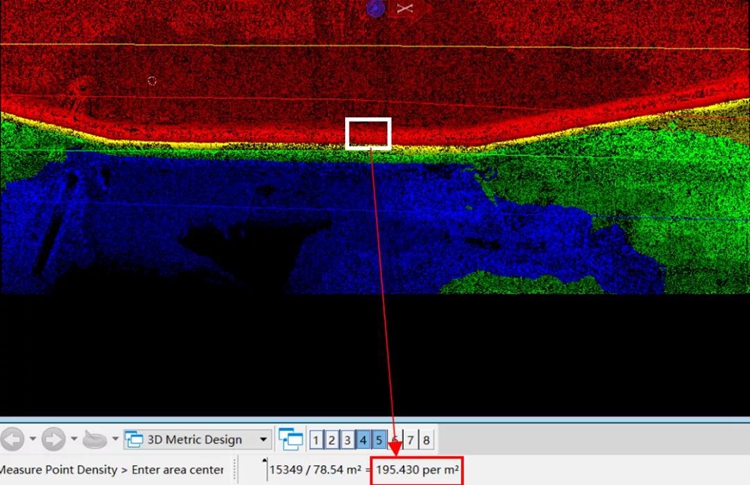

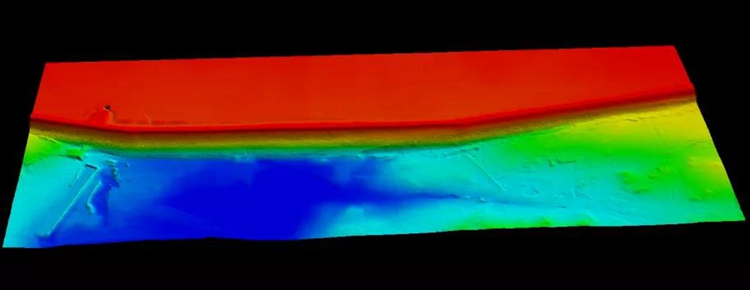

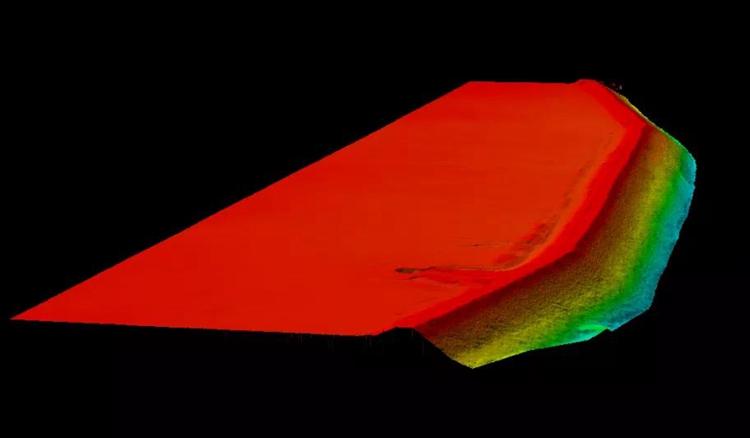

Through the denoising and classification processing of the point cloud data, the ground point data of the survey area is obtained, and then the tailings pond DEM (digital elevation model) is constructed to complete the entire operation.

Point cloud

Point density map: The point density on the slope of the tailings pond is about 195 per m²

Tailings pond DEM

In this exercise, Genius comprehensively demonstrated that in terms of emergency inspections in mines, the deployment of field operations is efficient and convenient, and the flight platform is directly mounted on the flight platform with one-click start.The equipment is simple to operate without complicated radar settings, and has outstanding advantages such as efficient flight operations and diverse results.The DEM of the survey area was constructed quickly and accurately, which enabled the company to smoothly and timely grasp the real situation of the surrounding area of the tailings pond.

Through this exercise, the Genius lidar system "shows its muscles" in the inspection scene of the mine tailings pond, which strongly proves the feasibility and reliability of the product.

More application scenarios

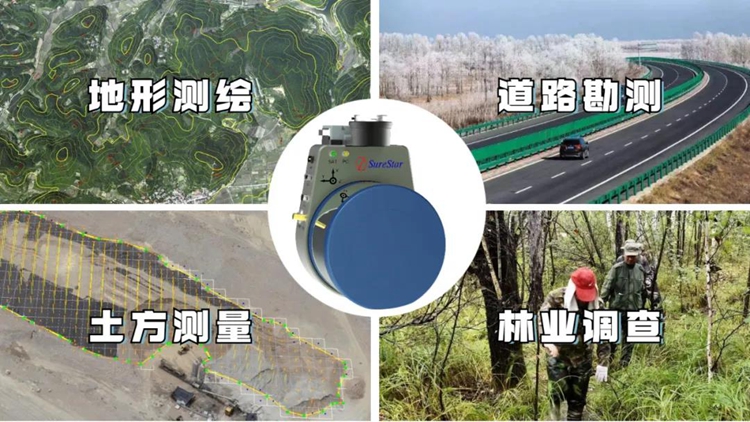

Surestar's profound accumulation in the field of lidar has created the comprehensive and outstanding capabilities of the Genius lidar system. Genius are widely used not only in mine surveying scenes, but also in topographic surveying and mapping, forestry surveys, road surveys, earthwork surveys and other fields.

The maximum total weight of the Genius system is only 1.7kg, and general light drones can easily carry it for operations. In addition, Surestar also provides mature and rich configuration solutions for the collaboration of different flying platforms, different cameras and Genius lidar systems. Customers can freely match accessories to complete the personalized configuration upgrade of the Genius system according to specific project needs.

This miniature LiDAR system that integrates 16/32-line lidar scanner, high-precision POS system, internal control unit and 42Mp high-resolution SLR camera can obtain 3D point cloud and image data in the field of view simultaneously during flight. And can quickly generate 4D products such as DEM, DOM, DSM, DLG, etc. on demand to meet the needs of surveying and mapping operations in different fields.

The lidar scanner used by the Genius system has a maximum range of 250m, a range accuracy of 2cm, and a measuring point frequency of 320 kHz/640 kHz. Together with the high-precision inertial navigation system, it effectively guarantees the three-dimensional space of the Genius during flight. High accuracy and completeness of data collection.

In addition to parameters and functions, Genius brings customers more reasons to choose it. As a national high-tech enterprise with independent research and development capabilities for high-end lidars of surveying, mapping and navigation, Surestar has complete product independent upgrade and maintenance capabilities to fully guarantee customer after-sales service and upgrade needs; 7*24 hours after-sales service System, solve customer's after-sales problems in a timely manner, protect the interests of customers, and provide strong support for partners. For customers, choosing Genius and Surestar means choosing the continuity, batch, stability and precision of the project.(www.isurestar.net)