Has the shackles that have been plagued and hindered the development of lidar, such as high price, large size, and difficulty in mass production, have been broken? A set of 128-line lidar in the United States last year was priced at 90,000 U.S. dollars. What is the price of 256-line lidar now? What is the technical route of lidar? Which one is closer to the car-level, so as to help the lidar to "get on the car" for mass production faster? Let us listen to the interpretation of Surestar CEO Zhiwu Zhang who has been in the forefront of lidar technology for 15 years.

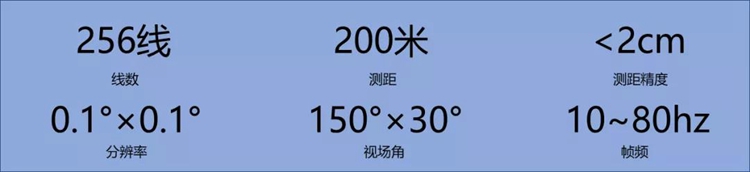

In terms of performance, the 256-line product meets the requirements of long-distance perception and discrimination of people, cars, and objects under high-speed vehicles. Taking at least 5 points in both vertical and horizontal directions as a stable detection standard, the resolution of 0.1°×0.1° can increase the effective range to nearly 200m. The 150° horizontal field of view can provide a wide field of vision in difficult scenarios such as unprotected left-turning of autonomous vehicles. In this way, car or pedestrian on the right side is taken care of, and the ultra-high frame rate can quickly capture abnormal events, and the fine grayscale recognition can provide powerful lane line perception.

Let's take a look at the parameters of the 256-line lidar:

"In fact, as early as the fall of 2017, Surestar has taken the lead in launching the C-Fans-64 line principle prototype using the micro-rotating mirror technology route. In 2018 and 2019, Surestar developed two products, C-Fans-128 and C-Fans-32, according to customer requirements," said Zhiwu Zhang.

Looking at the current automotive lidar market, it can be found that several giant companies in the world have followed closely behind and adopted the micro-rotating mirror technology route in their products.In terms of wiring harnesses, Surestar has achieved 256 lines, which is currently unmatched.

Surestar's C-Fans series products are aimed at the front-loading mass production market, taking into account performance, reliability and longevity. "We have passed 16949 (Quality Management Certification System for the Automobile Industry), and passed a series of reliability tests for car regulations under the "ISO 16750" standard. C-Fans has experienced the rigorous test of unstructured roads where field users placed it in the extremely cold northeast of minus 40 degrees and summer Gobi exposed the car body to more than 70 degrees.C-Fans has been installed at the end of the road by a car-road cooperative user for more than a year. It has experienced wind, frost, rain, snow, sun and rain without any problems. "Zhiwu Zhang said.

In terms of price, the unit price of 100,000 units of Surestar's 256-line products reported to car companies for bulk purchase is enough to surprise people. It can be said that Surestar has fully prepared for the mass production of car gauges.

Capital blessing, technology-driven, Vehicle Lidar accelerates the process of getting on

"In recent years, there have been many innovative entrepreneurs in the field of lidar detectors at home and abroad, and a large number of players have poured in, hoping to bring lidar into every car, so that capital can be realized, and the industry can land. This has become a new development in the automotive industry. Trend." Zhiwu Zhang said.

It is worth mentioning that many head technology companies in other fields have also moved to the field of lidar. After trying various technical route explorations and experiments, most industry giants chose a multi-faceted prism scanning technology system similar to Surestar C-Fans, also known as the "micro-rotating mirror scanner architecture." Surestar felt both gratified and somewhat pressured.

"Before and after 2017, as long as you do Lidar, the entrepreneurial team will not be unable to raise money, and it is very easy to start at least 10 million yuan, and 30 million yuan is very easy." Zhiwu Zhang said that in those two years, Lidar was sought after by capital hot money. At least hundreds of lidar start-up companies were born in China.

With the pursuit of capital, ripples have emerged in the field of automotive laser radars, and the news domineering propaganda of various laser radars "on the car" test has impacted people's attention. After all, it is the ultimate goal of car-mounted lidar that lidar is mass-produced on the production line together with automobiles, otherwise it will be regarded as a boast by the industry.

At present, the vehicle-mounted lidar is still in the early stage of industrial development, and the dispute over the technological development path is still inconclusive. For example, Tesla has always relied on computer vision technology, using on-board cameras to implement related autonomous driving assistance technologies. One of the reasons Tesla did not choose the lidar route is to control costs. However, "In terms of intelligent driving, Tesla can only be counted as assisted driving, not high-level autonomous driving." Zhiwu Zhang said.

With the continuous advancement of technology, from the new "expensive" to the new "favor", and then to the top of the station, the prospect of lidar is attractive. The data shows that by 2022, the global lidar market is expected to reach 5 billion U.S. dollars, and it is expected to exceed 80 billion U.S. dollars in 2035. It can be seen that the automotive lidar market is large enough. Therefore, targeting the automotive pre-installation market and deploying car-level products is also a logical development direction for lidar companies.

"It should be noted that compared to the aftermarket, the lidar front-end market (upstream mass production) is a large-scale job, and mass production is not easy." Zhiwu Zhang reminds entrepreneurs that the car factory will have a new model , It is a marathon of full sprint.

For example, Fu Xiaoqian, engineer of Surestar, said that if a car has 100,000 parts, a good model must sell at least 30,000 to 100,000 vehicles a year. This car company must guarantee 10% of the 100,000 vehicles. Ten thousand parts are not wrong, this is called mass production.

In any case, the lidar has been pushed to the high platform, and the process of "getting on the car" is accelerating, and even the arrow is on the string.

Micro-rotating mirror technology is easier to get on the car

Lidar is hailed as the "eye of unmanned driving" by the industry. Since 2016, with the rise of artificial intelligence and autonomous driving concepts, lidar has been used as a core sensor necessary for autonomous vehicles. Experts in the automotive industry said that in the field of high-level autonomous driving, lidar has become the main auxiliary sensor for L3 level autonomous driving mass-produced vehicles; and for L4-L5 level autonomous vehicles, lidar will become the essential primary sensor.

"In fact, lidar technology is very new. There is no recognized best and most mature technology system, there is no perfect and mature supply chain, and there is no national standard at all. The entire industry is in the stage of exploration, breakthrough, and re-innovation." Zhiwu Zhang said.

So, how does lidar work and what are the technical routes?

Lidar is composed of three parts: a laser transmitting and receiving system, an optical system and a signal processing system. It can help the computer on the car quickly, efficiently and accurately capture the surrounding three-dimensional images, and measure the distance and speed of the object.

Its working principle is that by driving the laser transmitter to actively reflect the light source (visible light and near-infrared light waves) to the detection object, when the light returns, the lidar can calculate the distance of the object and whether the object is moving. Therefore, lidar is an indispensable and important sensor in autonomous driving, and it is the eye and all-weather perception system of intelligent vehicles.

In terms of device structure, laser radar has mechanical laser radar and solid-state laser radar. Specifically, the laser transmitting and receiving modules of mechanical lidar rotate during work, and obtain a 360° field of view through rotation, which makes the reliability and stability of mechanical lidar poor. In addition, the price is high and the size is high. Large, unable to pass the vehicle regulations, complicated processes, and low production efficiency are all bottlenecks in the mass production of mechanical lidar.

Let's look at solid-state lidar again. Its laser transmitting and receiving module is static in operation, but the optical mechanism can be static, and it can also be driven by a circuit (such as a MEMS micro galvanometer) or a micro motor (such as a micro rotating mirror) to drive, control and adjust the angle. Among them, the MEMS technology path was once favored by many manufacturers due to its low cost advantage.

However, three bottlenecks of MEMS currently need to be broken through: First, its field of view is relatively small, and the field of view of a single MEMS lens is only about 30 degrees. The field of view is small and the blind area is large. Multiple lidars are needed to achieve 360-degree coverage of the horizontal field of view. Although some companies can achieve 120 degrees of MEMS field of view, they need to use 4 MEMS galvanometers to achieve this, which increases the complexity of the system and the difficulty of the process. The point cloud joints generated by the overlapping of galvanometers make automatic identification. The algorithm difficulty increases.

The second is that it has insufficient ranging capabilities. At present, MEMS using 905nm nano-semiconductor laser transmitters can only reach 80 meters, which is far from the 200-meter range required for autonomous vehicles. In order to overcome this drawback, some companies use 1550nm nanometer fiber lasers to make up, and the "expensive" fiber lasers have become a pain the industry cannot bear.

Third, fiber lasers are not resistant to high and low temperatures, and still cannot pass vehicle regulations. In addition, huge power consumption is undoubtedly the "fatal weakness" of automotive sensors.

"For automotive consumer electronics products, there is no choice but to be cheap, compact and adaptable to the environment." Zhiwu Zhang said bluntly.

Relying on its own years of exploration and heritage of lidar, Surestar launched the C-Fans micro-rotating mirror structure "in a unique way", taking the lead in miniaturizing and solidifying the laser transmitting and receiving module and signal processing module of the lidar, using a micro motor Drive the polygon mirror to scan, to achieve a large field of view, long range, high resolution, low-cost vehicle-gauge lidar technology path.

The five series of laser radar signal processing chips independently developed by Surestar are the guarantee of the performance and cost advantages of Surestar's C-Fans laser radar, as well as our unique core technology and capabilities. Surestar C-Fans-32 is currently the only lidar product that has passed "intrinsically safe" certification. It has been verified from the side that Surestar's independent chip has low power consumption, low starting current, and low heat production. The contribution from this aspect has ensured the safety of robots and unmanned vehicles operating in flammable and explosive environments such as coal mines.

Zhiwu Zhang said that avoiding technical paths that have obvious theoretical flaws, performance ceilings and cost bottlenecks have saved us a lot of research and development time. At the beginning of the design, Surestar car gauge lidar aimed at the following goals: one is cheap; the other is compact; the third is low power consumption; the fourth is strong environmental adaptability; the fifth is high reliability; the sixth is suitable for large Mass production.

Lidar needs industry chain joint innovation

"It's not easy to make a product." Zhiwu Zhang said frankly. For example, in the reliability experiment of micro-rotating mirror products, our products have to undergo vibration, shock, drop, fatigue, high and low temperature, immersion, electromagnetic interference, etc. "torture". The performance that meets the car regulations is polished step by step in this way.

"More important is innovation and integration." Zhiwu Zhangu said, Lidar has a wide range of uses, and can be used in various vehicles such as security, inspection vehicles, forklifts, vans, etc., including inspection robots, and can also be used in smart cities and vehicles. Road synergy and other fields have been well applied. All these need to be driven by innovation and technology integration.

Take the fusion of vehicle-mounted lidar and millimeter-wave lidar as an example. The advantage of millimeter-wave radar lies in all-weather and all-weather, but it has low resolution and low accuracy. It only knows whether there is any object, and it cannot distinguish what it is; while lidar It is all-weather, but not all-weather, with high resolution and high accuracy. What is lacking is the advantages of millimeter wave radar, which is greatly affected by rain and snow, and the detection range will be attenuated, and some reflected signals will be easily lost. If these two kinds of lidars are connected together, they can complement each other. There is also a camera, which can distinguish colors, which is incapable of lidar. Therefore, in the future, sensors must be complementary, perform their own duties, and work together to contribute to the country's social governance capabilities and governance modernization. The more such innovations, the better.

The lidar market is very large and the industrial chain is also very long. It requires the full cooperation of the entire field, the entire industry, and the entire ecology in order to work together to make the industry bigger and stronger.

First, we must focus on solving user pain points to achieve innovation-driven and create valuable products. If the product developed can only serve as the icing on the cake, it will certainly not succeed, or it will not easily achieve the set goals. Therefore, it must be the only need to solve the user's pain point, and this pain point is real.

For example, we are more optimistic about two industries, one is national defense and the other is agriculture. Modern national defense and public security must be highly automated, and lidar is of great use. At present, rural labor is scarce, especially the difficulty in recruiting in the breeding industry. Unmanned driving is precisely aimed at the pain point of the rural labor shortage and solves the problem of labor in the breeding industry.

Second, it is necessary to calculate economic accounts and create value for users. Facing the economic downturn in 2020, Surestar has achieved positive growth, among which UAV LiDAR products have increased by 80% year-on-year. How is this done? It is because it solves the pain of the threshold and efficiency of airborne lidar, and solves the pain points of users. Our products have a high pass rate of collected data, which not only helps users save money, but also helps users make money.

Taking a real case of power inspection as an example, the "Genius" drone airborne lidar system developed by Surestar can inspect 30 kilometers of power transmission lines every day. If a company can receive 3,000 kilometers of electricity inspection orders a year on average, basically two people can finish their work in two or three months, which saves manpower and is efficient, and the benefits are very obvious. In addition, our self-developed chips have also played a vital role in deepening the product moat (competitive advantage).

"Genius" UAV Airborne Lidar System

Some people say that the lidar industry is very large and the industry chain is very long, so large that “the combination of the mobile phone industry and the camera industry is the lidar industry chain.” I think the lidar industry is indeed larger than the camera, and fierce competition will eliminate it. For a group of startup companies that are not deep in the moat, there should be 5-10 large-scale lidar companies on the market in the future.

At the moment, the vehicle-mounted lidar has entered the battle of the midfield. In any case, companies must stay alive to wait until the day when the lidar is "on the car". In other words, the mass production of lidar vehicles is a major event that requires collaborative innovation in the industrial chain, supply chain, and technology.(www.isurestar.net)