Genius makes heap measurements easier

Genius+DJI-300+PP-RTX

Backgroud of Case:

For the volume measurement calculation of wood, sawdust and other accumulations, the common measurement methods are total station measurement and GNSS measurement. However, for the survey areas with complex terrain and large range, the traditional survey methods are often faced with such problems as low work efficiency, high labor intensity, poor real-time performance, low measurement accuracy and poor environmental adaptability.

Airborne Lidar measurement overcomes the shortcomings of traditional measurement and provides a new technical means for heap measurement because of its advantages such as non-contact, fast scanning speed, full digitization, large amount of information, strong real-time, high measurement accuracy and strong adaptability.

Survey area Overview:

The project site is a forest farm factory, and the measurement object is the wood and wood chips in the factory.

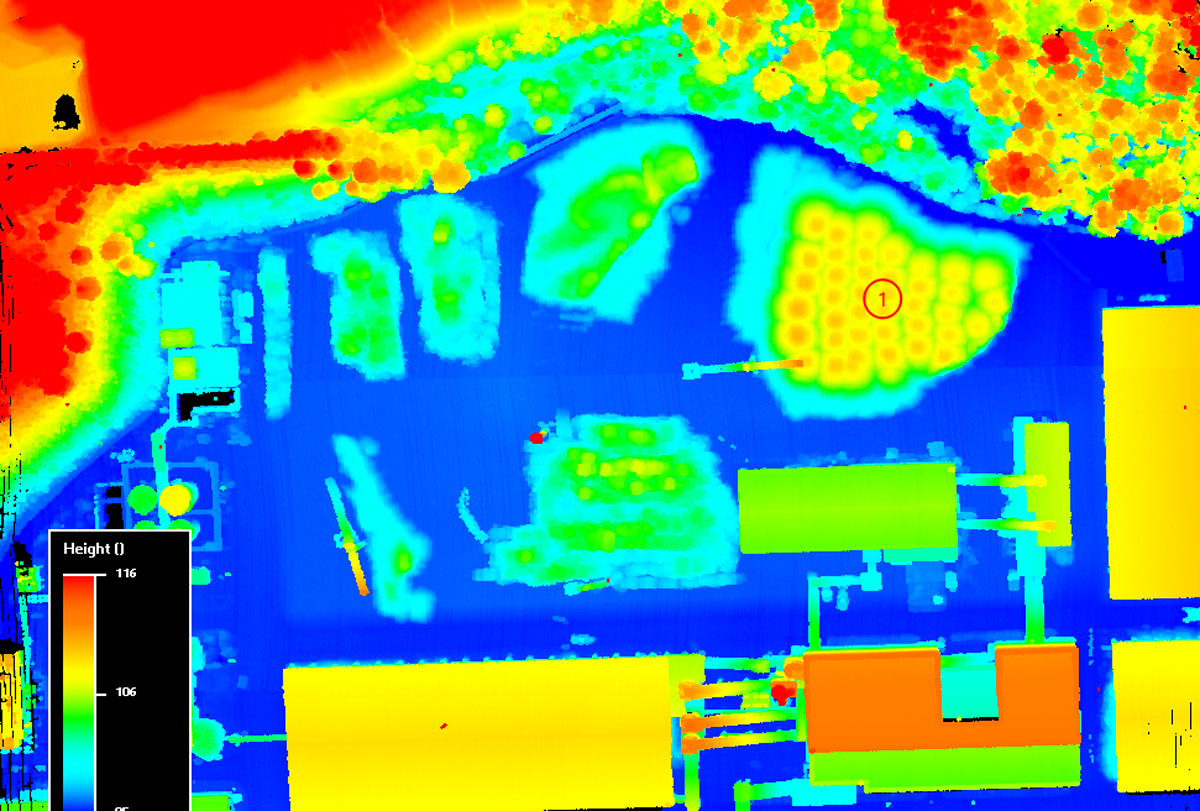

Overview of survey area

Overview of survey area

Project plan:

Lidar system:Genius;

Mounted flight platform:DJI M300 RTK;

Trajectory data solving mode: PP-RTX(Post-processed Centerpoint RTX)Free basestation service

1.Filed data collection

1.1 Route plan

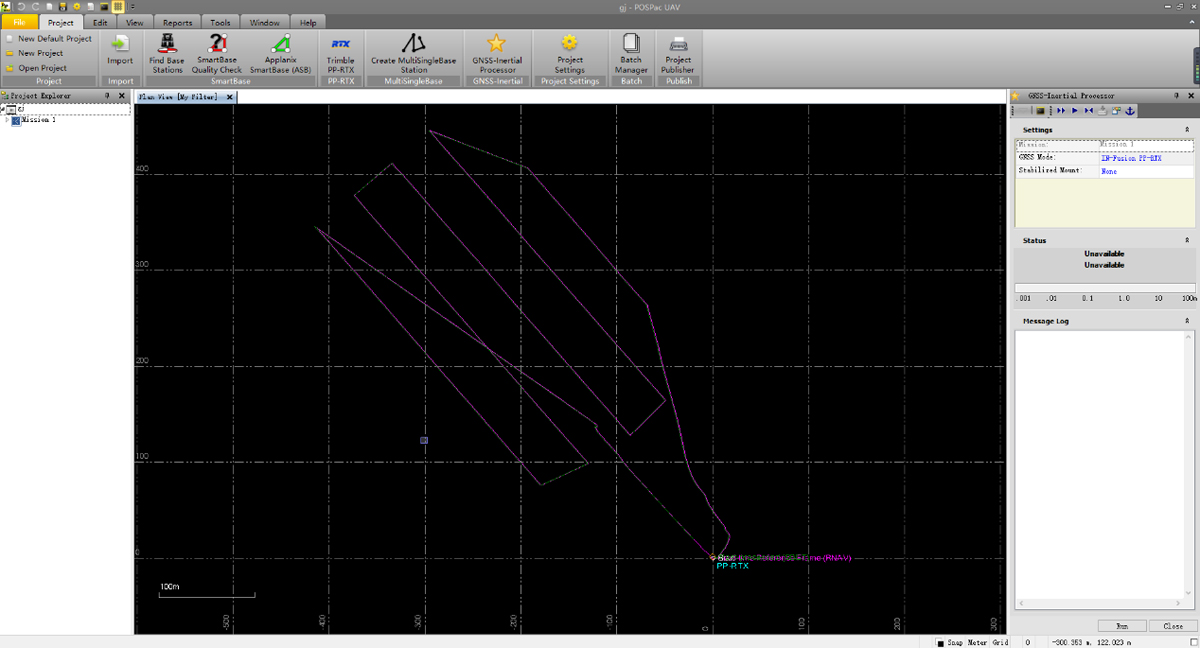

The flight parameters of the Genius airborne Lidar are set according to the range line of the survey area and the flight route is automatically planned by the flight planning software. The flight parameters are as follows: relative flight height is 100m, flight band spacing is 50m, and flight speed is 5m/s.

1.2 Flight work

The post-processing method of PP-RTX data is used in this flight operation. There is no need to set up a base station on the site: Genius is mounted to DJI M300 UAV and uploaded to the airline, after the inspection equipment is in normal condition, start the flight operation.

2.Data processing

2.1 POSdata solving

The PP-RTX module of POSpac software is used for post-differential processing to obtain high-precision flight trajectories, so as to ensure the quality of point cloud data.

2.2 Lidar point cloud data solving

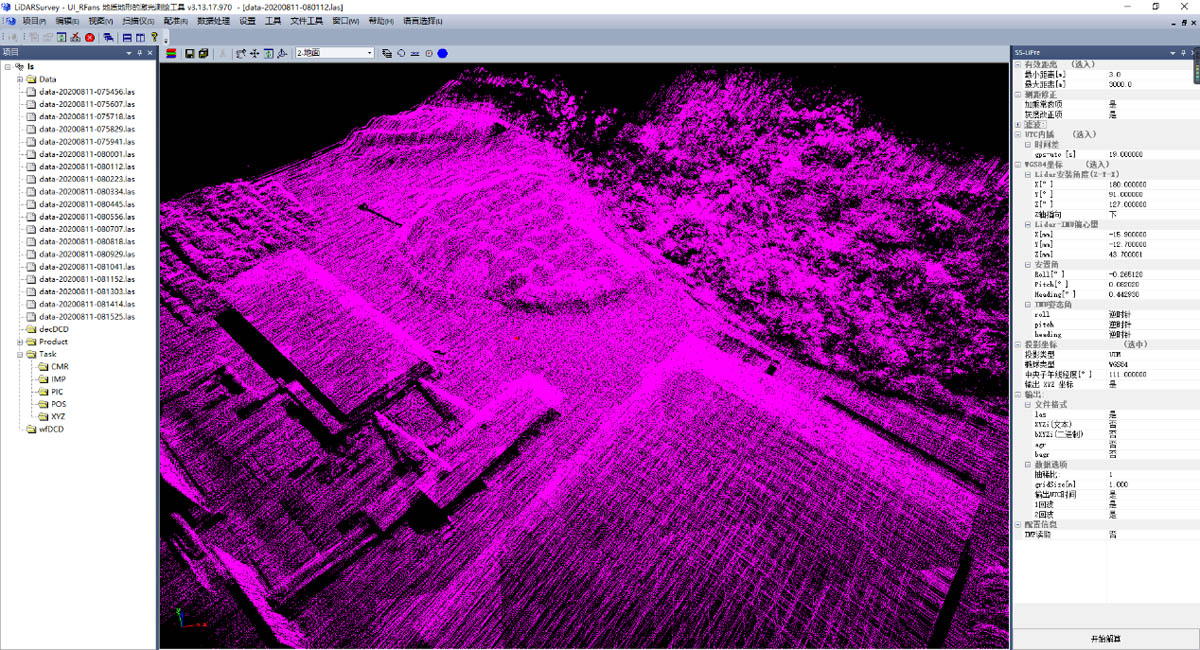

SS-lipre, a point cloud preprocessing software independently developed by Surestar, was used to fuse original lidar data and track data collected by Genius to generate LAS point cloud data in standard format.

2.3 Point cloud post-processing

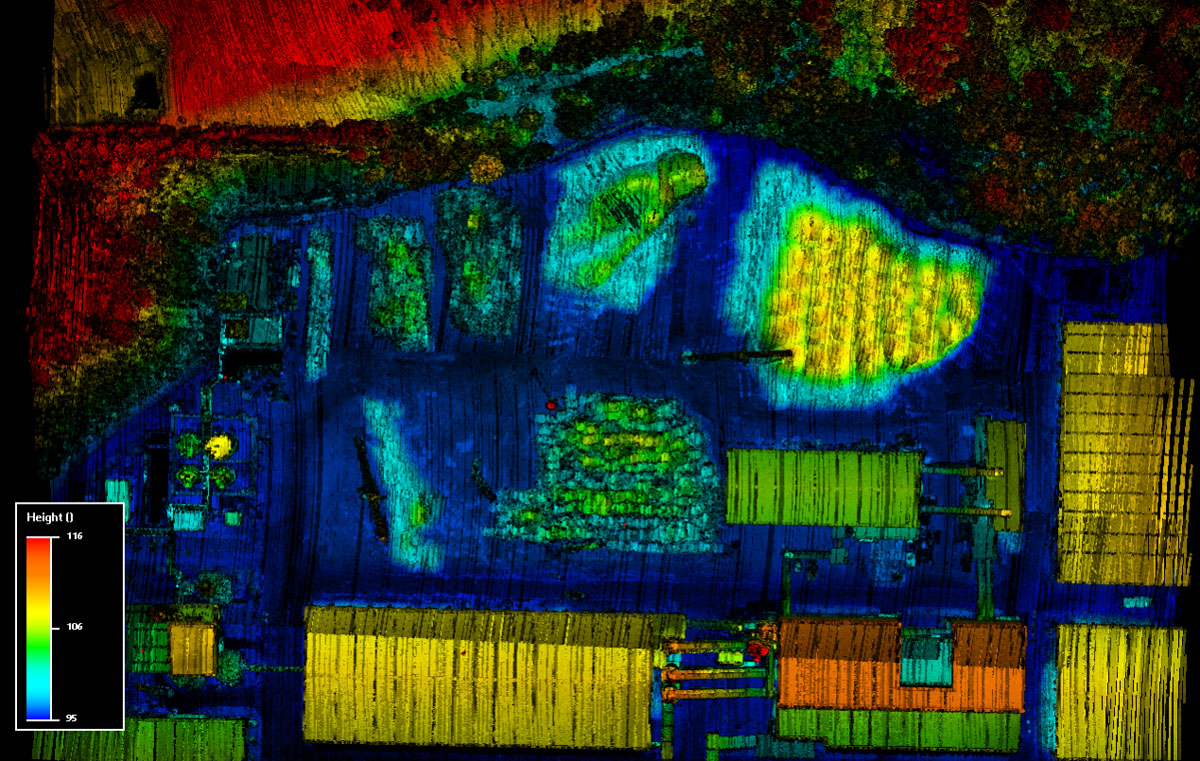

Check point cloud quality and use point cloud post-processing software to make denoising and classification.

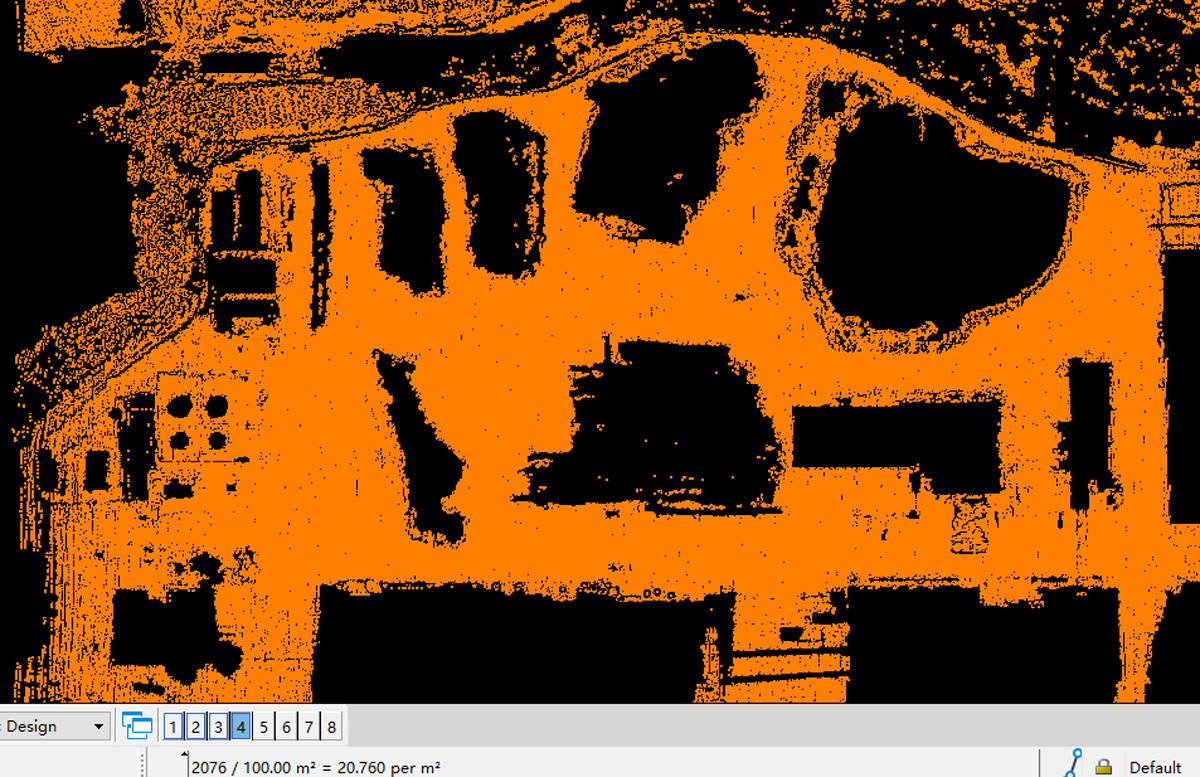

The classified ground point density can reach 20 points per square meter.

3.Calculation of heap volume

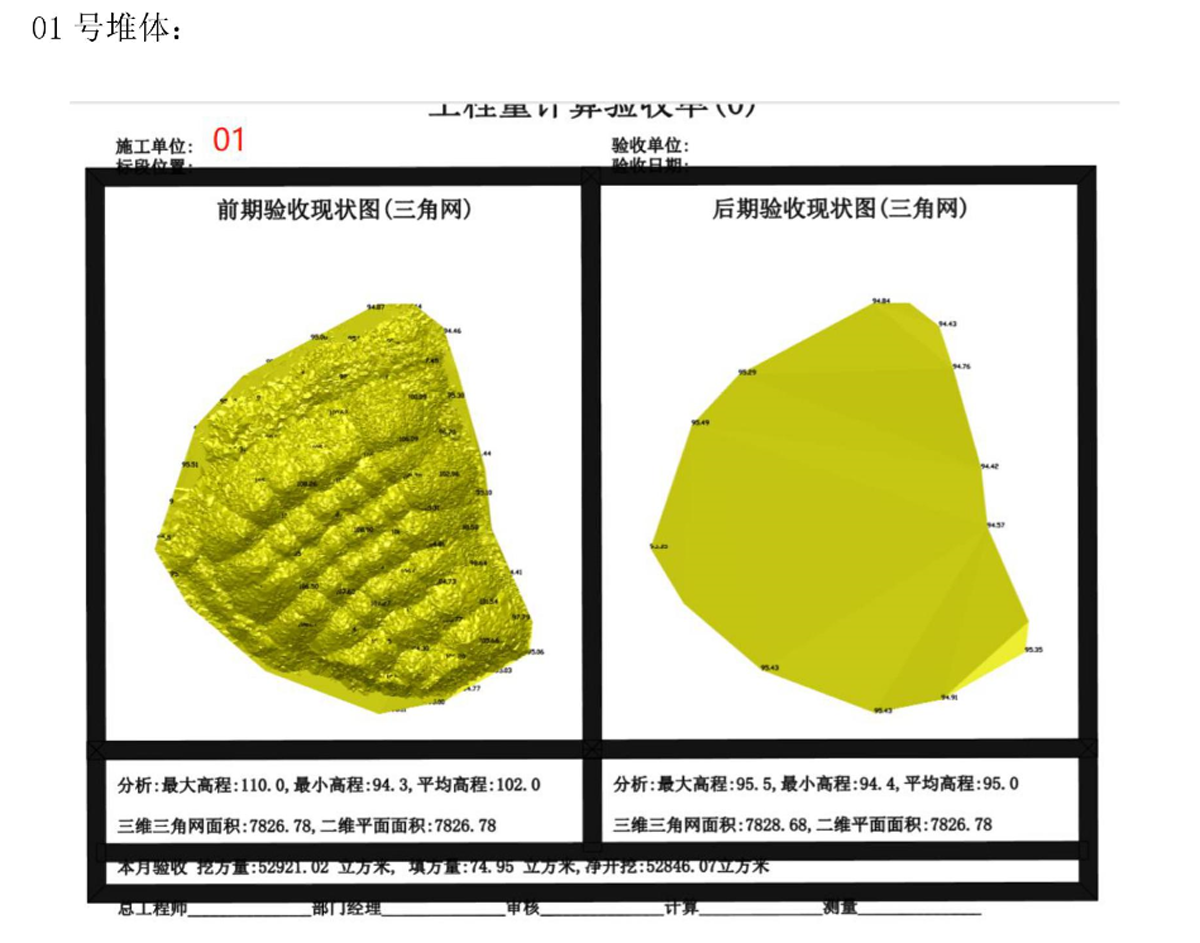

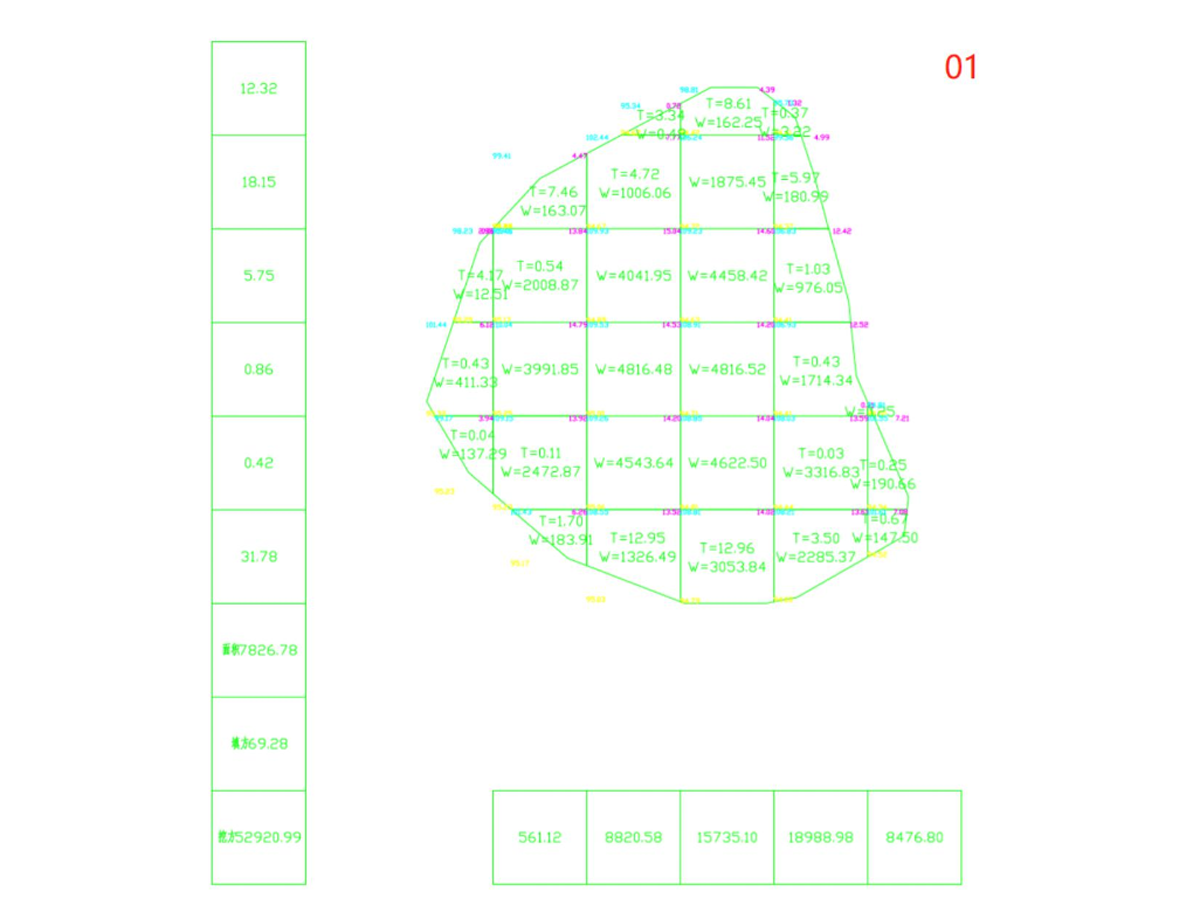

The volume of the heap is calculated automatically and accurately by using the supporting post-processing software, and output the corresponding volume calculation report.

Schematic diagram of heap number

Heap calculation results

4.Conclusion

4.1 Traditional surveying methods based on total station and GNSS often have inefficiencies, incomplete information and certain potential safety hazards. Especially in survey scenarios with large survey areas and complex field operating environments, traditional surveying and mapping methods are difficult to simultaneously meet the requirements of strong timeliness and high precision.

4.2 The operation mode of Hummingbird+M300+PP-RTX has the advantages of convenient outfield flight, low labor cost, complete post-processing software, and high results processing efficiency, which can well overcome the shortcomings of traditional surveying and mapping, This operation mode has great advantages in terms of work efficiency and project cost.